Work Principle:

With dual impellers rotating and agitating, ore pulps move downward and then diffuse along damping plate. Air is fed in tank from the lower end of shaft, and blended with ore pulps to form uniform suspending mixed liquid.

In the gold cyaniding process, leaching agitation tank is applied to leach and carbon-absorb ore pulps whose fineness is -200 meshes and whose density is less than 45%. Under similar circumstance, it is also applied to agitation and leaching in metallurgy, chemical and light industry.

Product Introduction:

Leaching Tank also called Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design

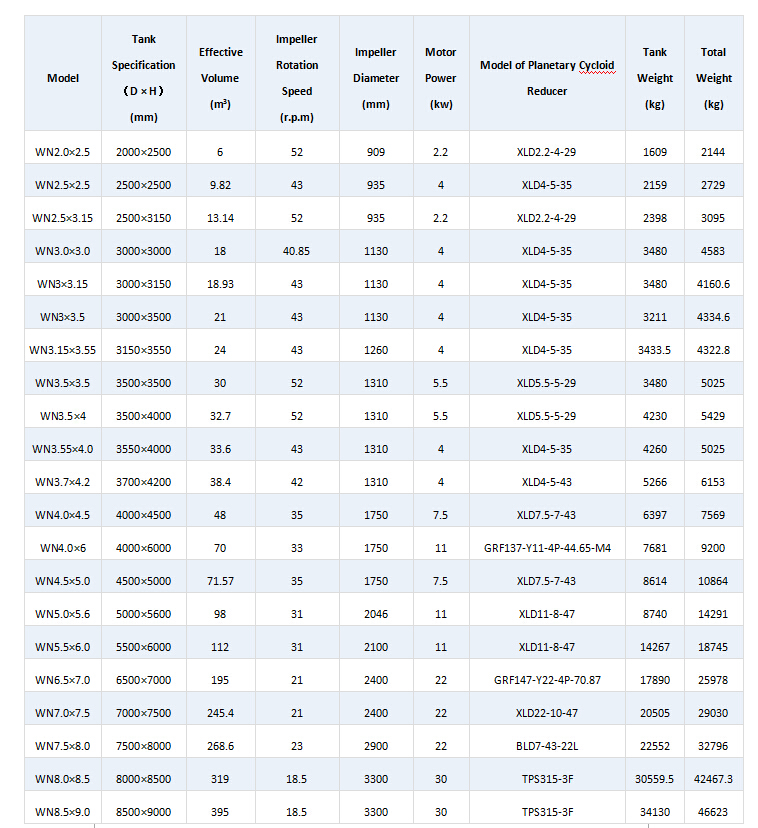

Effective Volume:

6-395m3

Product Improvement:

Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform inflation

Technical Data:

You can get the price list and a WinnerMac representative will contact you within one business day.

Copyright © 2015.WinnerMac All rights reserved.WinnerMac